Build Better / Multi-Unit Dwellings

Continuous insulation ticks H1 box for low-rise multi-unit developments

Now that clause H1 updates to insulation requirements are mandatory, architects and construction teams are adjusting their practices to build better-quality buildings. H1 means change, but change is a good thing when it means New Zealanders can enjoy homes that are warmer in winter, cooler in summer and drier all-year-round.

When it comes to designing and constructing low-rise multi-unit residential developments, thermal bridging impacts demand a fresh approach to insulation. By adding rigid continuous insulation to the exterior or interior of the building envelope it’s easy to achieve the new requirements.

Talk to one of our team about how Continuous Insulation can eliminate thermal bridging in your next building project...

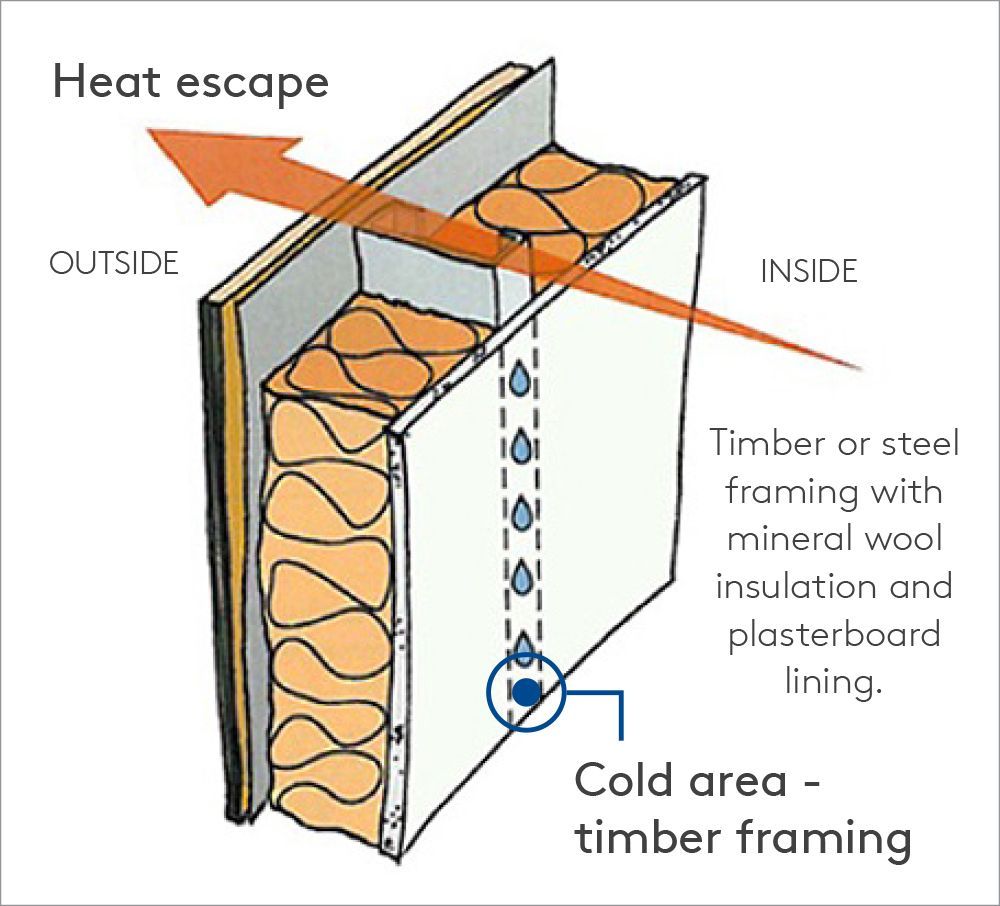

The problem with thermal bridging

Timber and steel studs, joists and other framing components make up a large portion of any wall. Without interventions, they provide a path for warm or cool air to escape, which reduces the energy efficiency of the building.

These pathways are known as ‘thermal bridges’, while movement of heat across a material that’s more conductive than the materials around it is known as ‘thermal bridging’. It can lead to condensation, and condensation can lead to timber and steel framing failure, mould and increased health risks.

More framing equals more thermal bridging

The characteristics of timber and metal-framed low-rise buildings provide many opportunities for thermal bridging. What’s more, new research funded by the Building Research Levy has found that the percentage of timber framing in the walls of new buildings is often higher than assumed in compliance calculations.1 They discovered that the average timber wall framing is 34%, which is 14%-18% higher than generally assumed. The maximum timber framing found in this study was slightly over 57%.

This is happening because building designers need to meet structure and weathertightness regulations. The knock-on effect is a decrease in R-values for two reasons:

- As the amount of timber framing in the wall increases, less space is available for insulation (see photo below).

- Additional timber in framing increases thermal bridging, which compromises the thermal performance.

1. The Wall Project research

Case studies showing a very high percentage of wall framing (left) and corner framing (right). These areas will be almost completely uninsulated.

What are the options to overcome thermal bridging challenges?

One way to achieve H1 requirements is to increase frame depth from 90mm to 140mm, to accommodate thicker bulk insulation. However, this adds to construction costs and reduces the building’s usable floor area.

A better and easier way to adapt to H1 is to add a layer of rigid continuous insulation to the exterior or interior of the building envelope, in addition to using bulk insulation within 90mm framing. This approach will result in R-values that meet or exceed the new H1 requirements.

How does rigid continuous insulation solve thermal bridging?

The term ‘continuous insulation’ means applying a continuous layer of rigid insulation across all structural members without thermal bridges, other than fasteners and service openings. Installed on the interior or exterior of the building envelope, continuous insulation acts as a separation layer between warm air and cold air. This achieves two benefits:

- It increases the R-value of the wall, ceiling or floor, making it easier to meet new H1 requirements.

- It reduces the risk of moisture damage in the building envelope by lowering condensation that results from vapour diffusion.

Kooltherm by Kingspan, New Zealand’s leading rigid continuous insulation product range

Kooltherm is a range of advanced thermal insulation boards for roof, wall and floor applications. Kooltherm products are typically used in high-quality multi-unit developments and homes.

With a fibre-free rigid thermoset phenolic core and a thermal conductivity of 0.022-0.023 W/mK (compliant to AS/NZS 4859.1:2018), Kooltherm products are the thinnest commonly used insulation materials for achieving the new H1 requirements.

Two ways to use Kooltherm:

1. Kooltherm K12 Framing Board can be installed in front of wall framing.

It delivers the highest R-value of commonly available insulations. A hybrid system may also include the use of bulk insulation in the cavity to further enhance the wall system R-value.

2. Kooltherm K17 insulated plasterboard can be installed on the interior of a building.

It can be applied to concrete tilt slabs, block walls, timber/steel framed walls and ceilings.

Download our Continuous Insulation Flyer

Case study: Kāinga Ora social housing project: