Better Buildings for a Better World.

Build Better / Low Pitch Roofs

What’s your H1/AS1 insulation solution for low pitch roofs?

With housing roof R-values set to increase to R6.60 (H1/AS1) on 1 May 2023, how will you meet the challenge of insulating low pitch roofs? Small spaces simply can’t accommodate the bulk insulation and ventilation space required.

Under the schedule, calculation or modelling method, the new R-value for roofs across the country will mean that insulation thickness will need to be increased. Adding extra bulk insulation won’t be a problem for a steep pitched roof. But a low pitch roof seldom has enough ceiling space to accommodate extra thickness, especially when you consider the mandatory 25mm minimum air gap between insulation and roof underlay.

Talk to one of our team about our H1/AS1 insulation solution for low pitch roofs...

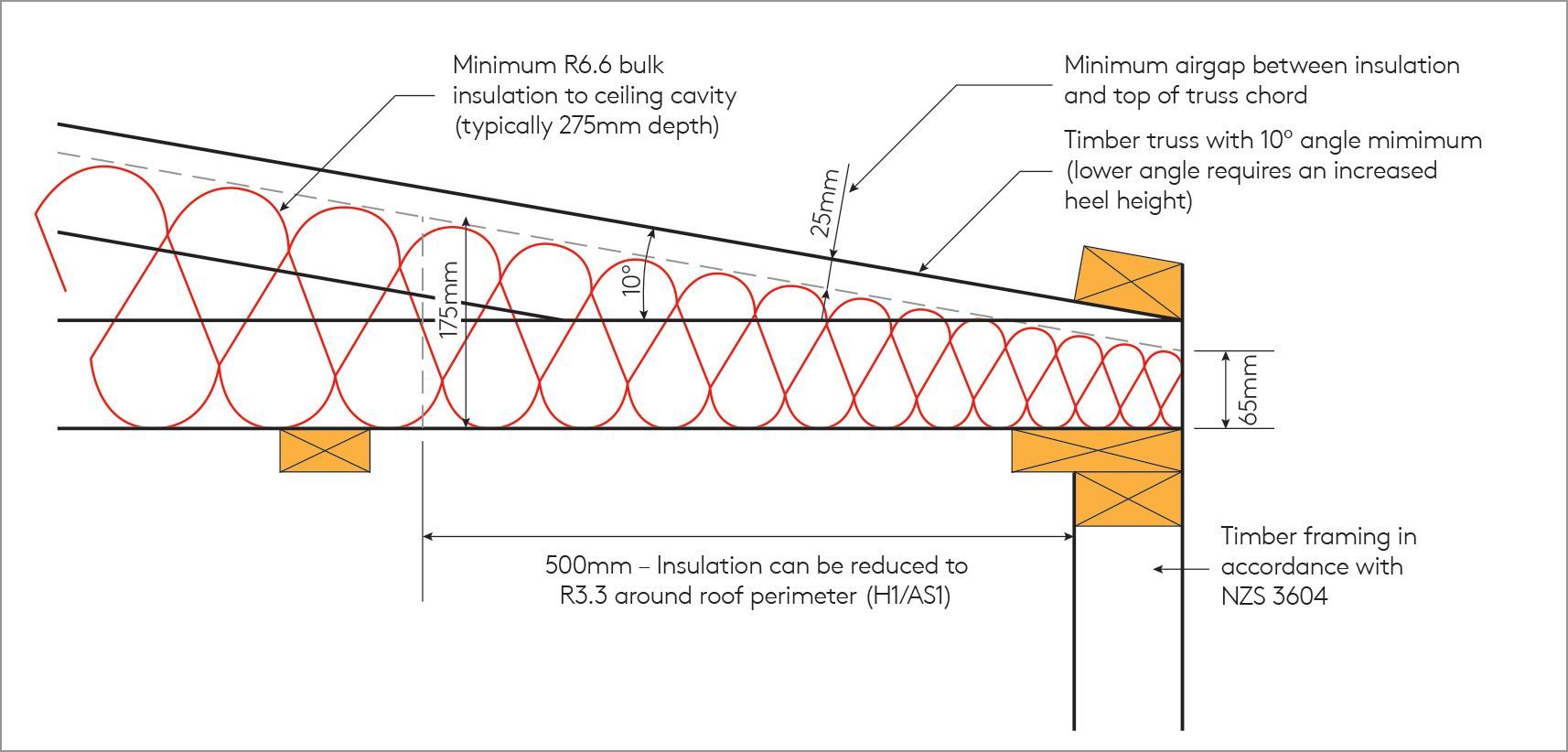

Within the new rules, it’s permissible to reduce insulation performance to R3.30 for a width of 500mm where the ceiling doesn’t allow the full thickness of insulation to be installed at its perimeter. However, this doesn’t really solve the problem. According to BRANZ*, to achieve construction R3.30, bulk insulation requires an installation depth of approximately 175 mm plus a 25 mm air gap to the roof underlay. So you need at least a 200mm space, even in the lowest areas of the roof. For this reason, the reduced insulation R-value at the perimeter of a low pitched roof has limited application. The below drawing shows bulk insulation being severely compressed at the roof perimeter - by up to 62% on a 10o pitch roof. A simple geometry calculation will tell you that the roof pitch without a raised heel design will need to be 45

o or greater to avoid compressing bulk insulation at the roof perimeter.

Increasing roof height isn’t a viable solution

One answer to this dilemma is to increase the roof height by raising the heel truss, but it’s a costly solution. And if the project is already designed to the maximum allowable build height, raising the heel truss is off the table entirely.

A smarter solution for a tight situation - Kooltherm by Kingspan

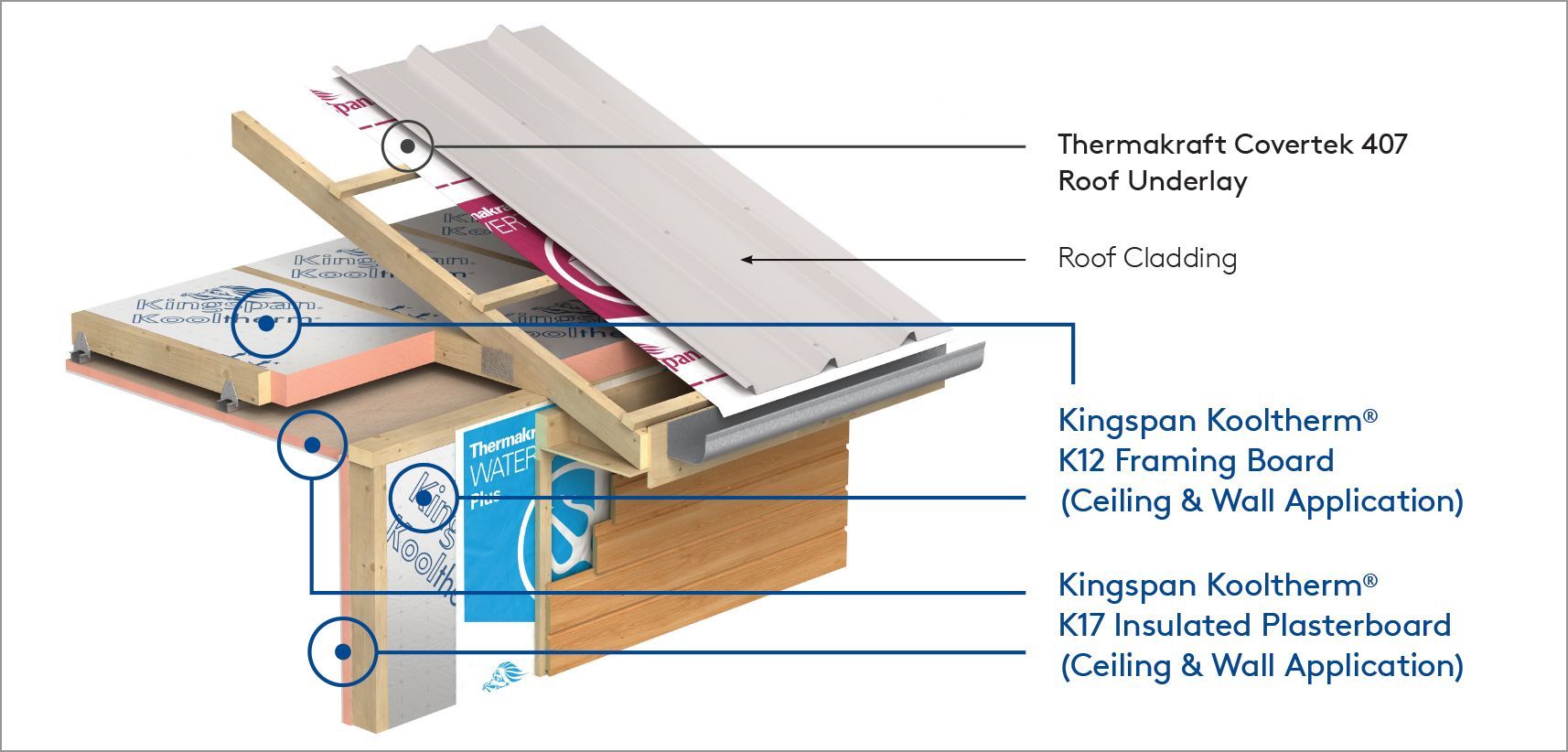

Kooltherm by Kingspan is New Zealand’s leading range of rigid continuous insulation products. It’s an effective and practical way to achieve the target R-value and is especially useful for low pitch roofs.

Adding a layer of rigid continuous insulation to the ceiling, in addition to using bulk or rigid insulation between the truss bottom chords, is the best way forward. It will result in R-values that meet or exceed the new H1 requirements. What’s more, thermal bridging in the ceiling can be significantly reduced or totally eliminated by using continuous insulation under the bottom chords.

A closer look at Kooltherm

The Kooltherm range of advanced thermal rigid insulation boards is suitable for roof, wall and floor applications in residential and commercial developments. Kooltherm board has a fibre-free rigid thermoset phenolic core and a thermal conductivity of 0.022-0.023 W/m.K (compliant to AS/NZS 4859.1:2018). Kooltherm products are the thinnest commonly used insulation materials available in New Zealand, so they’re the surest way to achieve the new H1 requirements in a low pitch roof.

Two ways to use Kooltherm in low pitch roofs

- Kooltherm K17 insulated plasterboard can be installed under ceiling bottom chords on a conventional truss. It can also be applied to concrete tilt slabs, block walls and timber/steel framed walls.

- .

- Kooltherm K12 framing board can be installed between bottom chords on a conventional truss, between wall studs and floor. It delivers the highest R-value of commonly available insulations.

Superior Performing Solution

More information

Technical advice for making the switch to Kooltherm call

0800 806 595 or email

technical@kingspaninsulation.co.nz

* BRANZ Magazine 161 page 40-42 H1 and sloping truss roof options

Can't find what you are looking for?

Get in touch, our team is always ready to help.

Products/Technical Information

Build Better

Building Systems

Contact

© 2023 Kingspan Insulation NZ Ltd |

All Rights Reserved

Kingspan Insulation NZ Ltd | All Rights Reserved