Better Buildings for a Better World.

Build Better / Condensation Management

Preventing condensation and mould in your roof cavity

As New Zealand’s leading manufacturer of permeable roofing underlay, we often get asked to explain why water droplets sometimes form on the underside of the underlay in ceiling cavities at colder times of the year.

Moisture travels up from living areas below

The air in a ceiling/roof cavity will always contain a certain amount of water vapour, which gets there from human activities below. Breathing, cooking, un-flued gas heaters, laundering and showering all generate water vapour that escapes into the roof cavity in various ways. In older homes water vapour escapes upwards through down lights, ceiling access holes and unsealed lining joints. In newer homes and totally-renovated homes, which are more airtight, water vapour diffuses into the roof cavity through solid permeable materials, such as wallboard and plywood. A family of four can generate up to 20 kilograms of water vapour per day. That’s a lot of moisture.

If the roof cavity is poorly ventilated, the air up there becomes over-burdened with moisture. When the temperature drops outside, this moisture can condense into water droplets (dew) on the underside of roof cladding and underlay, just like warm moist air condenses on a cold glass of water.

Underlay plays an essential role in helping water vapour to escape

Roofing underlay, whether it is building paper or a high-tech synthetic underlay, is in close contact with roof cladding. When the temperature drops outside, the cold energy is transferred to the underlay directly beneath the roofing iron or tiles.

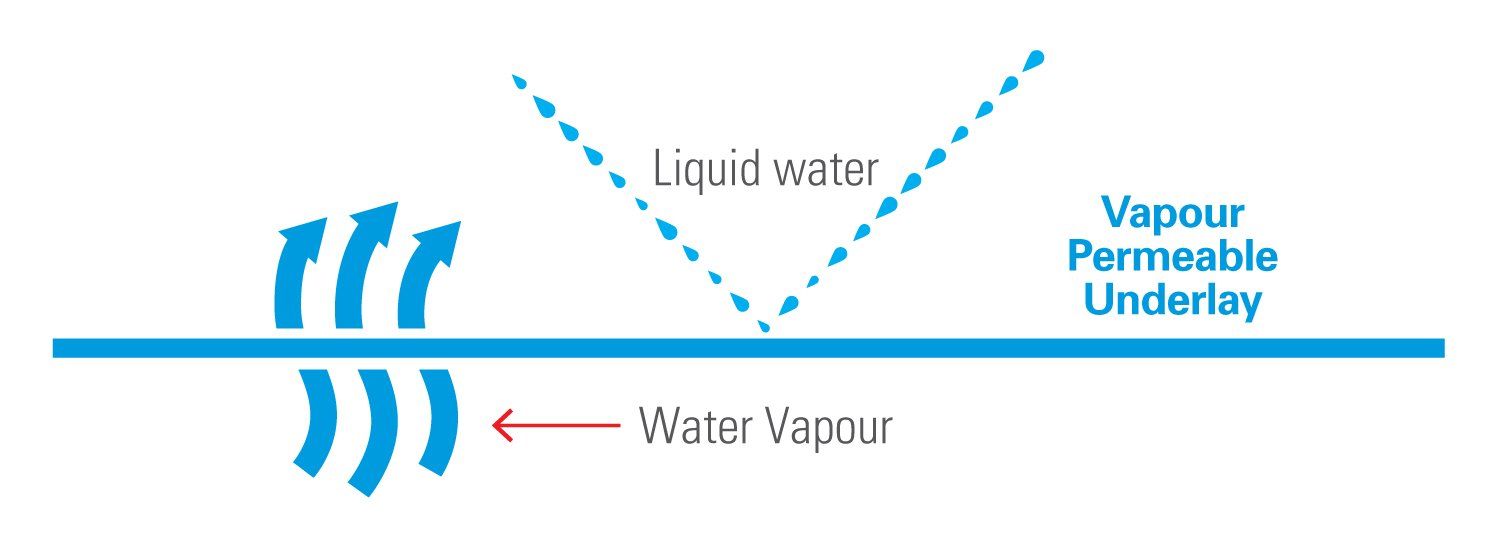

High quality permeable underlays, such as the Thermakraft Covertek range, are designed to hold excess moisture overnight (absorbent), then release it back into the atmosphere in water vapour form when the roof warms up the next day. While the membrane is able to effectively repel liquid water from the outside and prevent the roof from leaking, its permeability allows the escape of water vapour from the inside to the outside.

However, there’s a limit to how much moisture an underlay can absorb and release. If the condensation forming on the underlay is more than the underlay can effectively hold and release in a 24-hour period, water droplets may form. If this continues over a period of time, then conditions are ripe for the development of mould. Improving roof cavity ventilation is the only answer.

Black or kraft paper products exhibit the same condensation problem as synthetic underlay products, however their high absorbency and the dark colour hide the liquid moisture. When touched by hand in an under-ventilated roof cavity, the paper will feel wet. Black paper products do allow water vapour to escape to the outside, however the process takes longer than with advanced synthetic underlay products.

Roof condensation is a side-effect of modern building practices

Until relatively recently, New Zealand houses ventilated themselves. They either had purpose-built air vents or they naturally leaked air, due to old-fashioned building methods. Think about the classic New Zealand villas and bungalows, which are basically wooden tents and almost as breezy. These old homes usually have passive roof vents, plus their non-airtight construction allows water vapour to escape easily from gaps around the edges of roof cavities.

The other extreme arrived in the 1990s, when monolithic cladding came along to create airtight boxes that retained heat but also moisture. The result was modern homes with internal dampness and mould, which extended to their roof cavities.

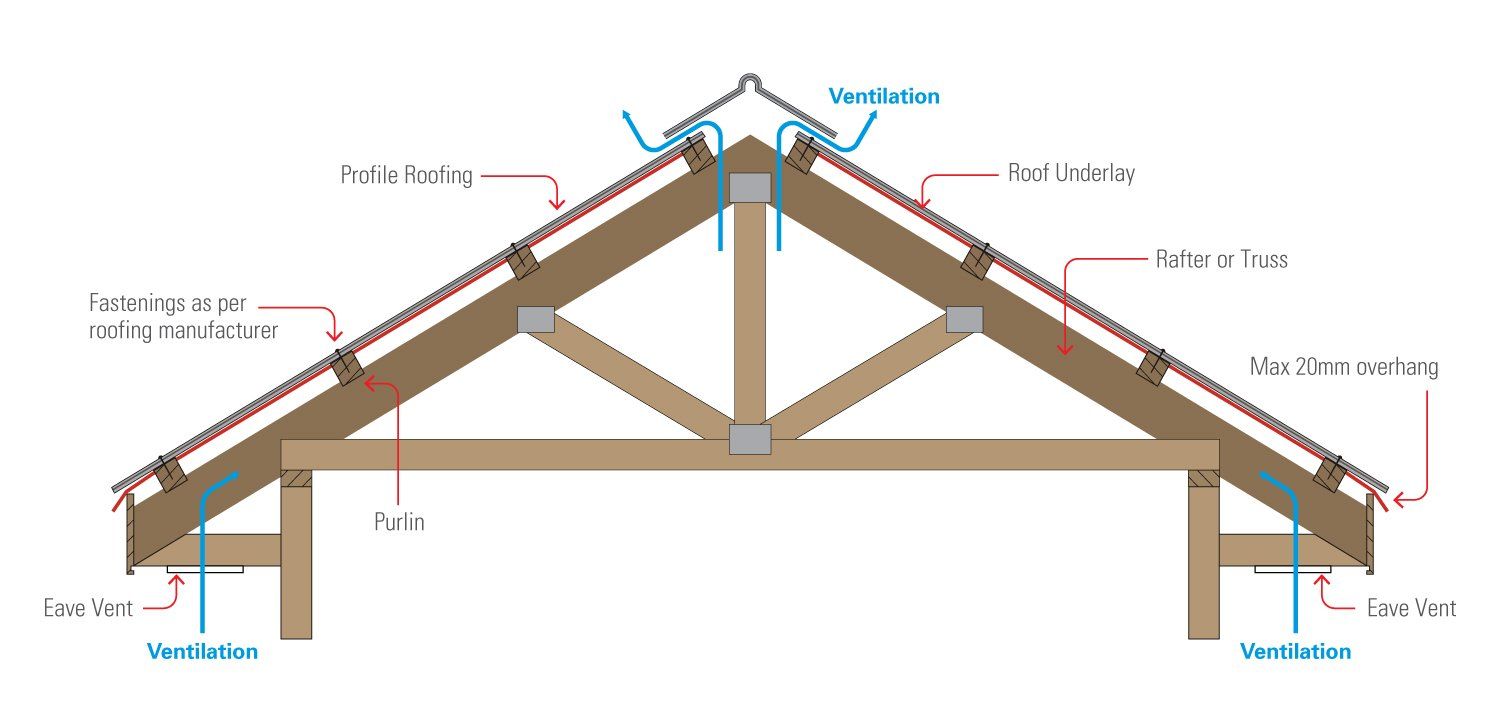

Today, the New Zealand Metal Roof and Wall Cladding Code of Practice (NZ MRM COP) V3.0 Section 10 outlines in detail the need to manage internal moisture in the building design, to ensure homes stay healthy. Ventilating roof cavities is part of this design process.

Ventilation needs to be both active and passive

Effective ventilation is where air is removed from the inside of the building and expelled to the external environment. It’s necessary for both the liveable space and the roof space. If your roof space is too airtight, drying of condensed surfaces takes too long or never happens. Only a small proportion of new builds incorporate ridge vents and eave vents to ensure water vapour can escape easily from the roof cavity. Underlay, whether it is building paper or a high-tech synthetic underlay, is in close contact with roof cladding. When the temperature drops outside, the cold energy is transferred to the underlay directly beneath the roofing iron or tiles.

For homes that are airtight, there are various ways to retro-fit roof cavity ventilation that will benefit the entire home. Best practice for home ventilation is ‘balanced pressure ventilation’ or ‘balanced heat recovery ventilation’. This involves actively drawing air from the outside and delivering it to the inside. Exhaust outlets are also installed inside the building to expel moist air to the outside. Active ventilation adds resilience to the building’s internal moisture management design, however passive/natural ventilation within a roof cavity is still critical.

Timely design prevents the problem

Managing moisture in the roof cavity to prevent unhealthy moisture levels and mould growth is a two-part process that involves effective ventilation and high-quality permeable underlay. In both cases, good decisions need to be made in the design phase of a new build or renovation project.

Can't find what you are looking for?

Get in touch, our team is always ready to help.

Products/Technical Information

Build Better

Building Systems

Contact

© 2023 Kingspan Insulation NZ Ltd |

All Rights Reserved

Kingspan Insulation NZ Ltd | All Rights Reserved